The Intricacies and Significance of Diecasting in Modern Manufacturing

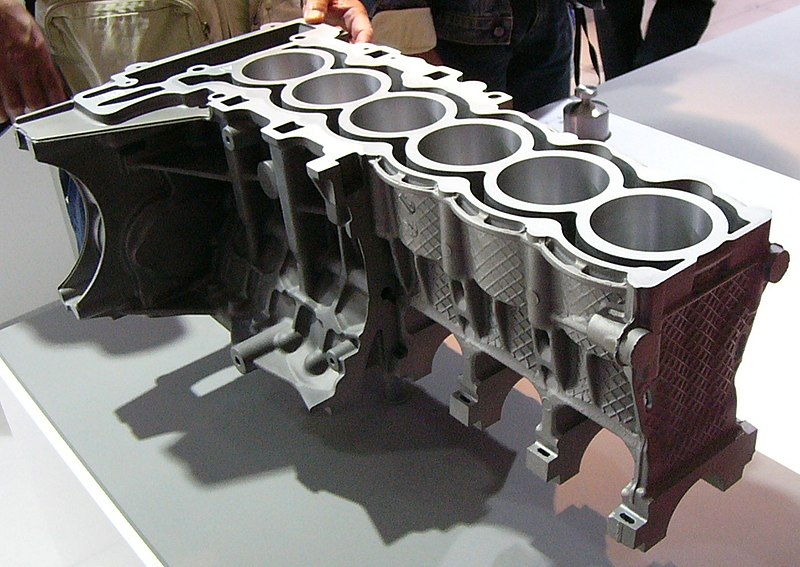

Diecasting is an extremely specialized manufacturing method that turns melts of metal into precisely-defined elements using high-pressure molds. The technique is now indispensable in a variety of industries, such as electronics, aerospace, automobiles and even consumer products due to its ability to make complex shapes with remarkable quality and precision. In combining the principles of metals with modern engineering diecasting can provide unrivalled precision and efficiency, making it a fundamental element of contemporary manufacturing. This article delves into complex world of diecasting by exploring its process, advantages and potential applications.  The diecasting process begins with the construction of the mold, or a die. The mold is made of hardened steel that can withstand extreme pressure and temperatures. Once the mold is prepared, metal alloys such as magnesium, aluminum, zinc or copper are heated up until they melt. The molten metal then gets put into the mold under extreme pressure. This ensures that it fills all parts of the mold, including detailed sections and thin walls. This pressure will be maintained until the material has solidified, at which point the die opens, and then the newly formed part is then ejected. The process is high-pressure, which ensures the product produced is precisely, with minimal need for any additional finishing or machining. One of the greatest advantages of diecasting is its ability to produce high volumes of parts. Once dies are cast this process is able to be repeated several times and with very little deviation between parts. It is important to repeat the process for industries that demand large amounts of homogenous parts. Furthermore, diecasting is known for its material efficiency. The process generates less waste than different metal-forming methods because any metal that is not used can be recycled and reused. This not only reduces the costs of manufacturing but also encourages sustainable manufacturing practices. The speed and efficiency of diecasting makes it a great alternative for the production of large volumes of pieces quickly and continuously, ensuring that manufacturers can keep to strict production deadlines and marketplace demands. Diecasting also excels in producing products with exceptional mechanical properties. Its rapid cooling of molten metal through the casting process results in fine grain structure that increases the strength and durability of the finished product. This makes diecast components particularly suitable for applications that require superior performance and durability. In the automotive industry they are employed in transmissions, engines as well as structural components, where the strength-to-weight ratio is crucial for vehicle efficiency and safety. Similarly, in the aerospace industry diecast parts contribute to the creation of light but robust structures, essential for optimizing performance and efficiency in fuel consumption. To acquire further details kindly go to Senadiecasting

The diecasting process begins with the construction of the mold, or a die. The mold is made of hardened steel that can withstand extreme pressure and temperatures. Once the mold is prepared, metal alloys such as magnesium, aluminum, zinc or copper are heated up until they melt. The molten metal then gets put into the mold under extreme pressure. This ensures that it fills all parts of the mold, including detailed sections and thin walls. This pressure will be maintained until the material has solidified, at which point the die opens, and then the newly formed part is then ejected. The process is high-pressure, which ensures the product produced is precisely, with minimal need for any additional finishing or machining. One of the greatest advantages of diecasting is its ability to produce high volumes of parts. Once dies are cast this process is able to be repeated several times and with very little deviation between parts. It is important to repeat the process for industries that demand large amounts of homogenous parts. Furthermore, diecasting is known for its material efficiency. The process generates less waste than different metal-forming methods because any metal that is not used can be recycled and reused. This not only reduces the costs of manufacturing but also encourages sustainable manufacturing practices. The speed and efficiency of diecasting makes it a great alternative for the production of large volumes of pieces quickly and continuously, ensuring that manufacturers can keep to strict production deadlines and marketplace demands. Diecasting also excels in producing products with exceptional mechanical properties. Its rapid cooling of molten metal through the casting process results in fine grain structure that increases the strength and durability of the finished product. This makes diecast components particularly suitable for applications that require superior performance and durability. In the automotive industry they are employed in transmissions, engines as well as structural components, where the strength-to-weight ratio is crucial for vehicle efficiency and safety. Similarly, in the aerospace industry diecast parts contribute to the creation of light but robust structures, essential for optimizing performance and efficiency in fuel consumption. To acquire further details kindly go to Senadiecasting  Diecasting's materials have a significant role to play in determining the properties and performance of the final product. Aluminum is among the most commonly used materials due to its high strength-to-weight ratio, corrosion resistance and excellent thermal and electrical conductivity. Zinc alloys are also popular for their strength, ductility, and the capability of creating components with fine details. Magnesium alloys benefit from the advantages of being the lightest steel, which makes them perfect for use in areas where weight reduction is critical. Copper alloys are somewhat less popular, are used because of their outstanding electrical conductivity as well as their resistance to corrosion. The material selection depends on the particular requirements of the job, such as mechanical properties, climate conditions, as well as cost aspects. Diecasting is an advanced manufacturing method that is able to combine high-quality, efficient and versatility. Its capability to manufacture sophisticated, high-end components that have superior mechanical properties makes it useful in a variety of industries. The efficiency of diecasting in mass production, along with the material and cost advantages, proves its worth in modern manufacturing. Since industries will continue to need top-quality and durable components Diecasting is a key technology driving innovation and enabling the production of innovative products that fulfill all the demands of a constantly changing market. By its continual advancement and use diecasting is a perfect example of the convergence of engineering excellence and manufacturing expertise.

Diecasting's materials have a significant role to play in determining the properties and performance of the final product. Aluminum is among the most commonly used materials due to its high strength-to-weight ratio, corrosion resistance and excellent thermal and electrical conductivity. Zinc alloys are also popular for their strength, ductility, and the capability of creating components with fine details. Magnesium alloys benefit from the advantages of being the lightest steel, which makes them perfect for use in areas where weight reduction is critical. Copper alloys are somewhat less popular, are used because of their outstanding electrical conductivity as well as their resistance to corrosion. The material selection depends on the particular requirements of the job, such as mechanical properties, climate conditions, as well as cost aspects. Diecasting is an advanced manufacturing method that is able to combine high-quality, efficient and versatility. Its capability to manufacture sophisticated, high-end components that have superior mechanical properties makes it useful in a variety of industries. The efficiency of diecasting in mass production, along with the material and cost advantages, proves its worth in modern manufacturing. Since industries will continue to need top-quality and durable components Diecasting is a key technology driving innovation and enabling the production of innovative products that fulfill all the demands of a constantly changing market. By its continual advancement and use diecasting is a perfect example of the convergence of engineering excellence and manufacturing expertise.